Automated Waste and Soiled Linen Systems: Simplifying Waste Management

An Automated Waste and Soiled Linen System streamlines and enhances waste management processes within a healthcare facility. It integrates cutting-edge technology and design to efficiently collect and convey refuse and soiled laundry, ensuring cleanliness, hygiene, and convenience. An automated waste and soiled linen system includes various elements, including load stations, Q-Chute™ staging, pneumatic conveying, and compaction which offers an easy-to-use, comprehensive approach to waste disposal and linen handling.

Is an Automated Waste and Soiled Linen Removal Easy to Use?

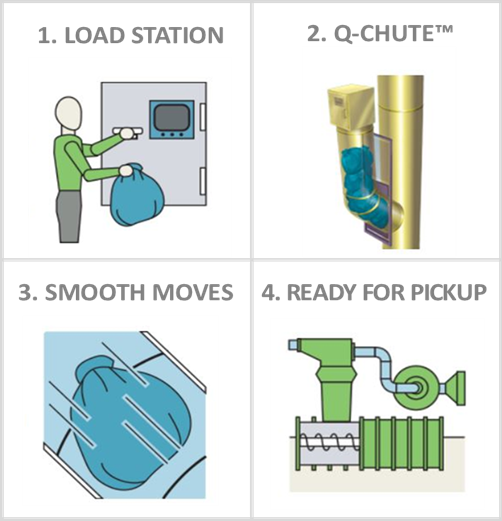

Undoubtedly, yes! For users, operating the system is as straightforward as following the sequence “1-2-3-4.” While the system’s usability is simple, it is important to note that staff training is essential to ensure optimal outcomes.

1. Load Station: A staff member places refuse or soiled laundry bundles into strategically located load stations equipped with secure touch-screen panels. This eliminates the need to manually transport unsightly waste bundles throughout the facility, contributing to a cleaner and more aesthetically pleasing environment for patients, staff, and visitors. Furthermore, the separate load stations for refuse and linen help contain waste and minimize the spread of harmful pathogens.

2. Q-Chute™ Staging: Inside the load station, bundles are stored within the innovative PAC Q-Chute™. This mechanism enables the swift loading of an entire cartload of refuse, recycling, or soiled linen into the system. Advanced computer controls facilitate the coordinated release of bundles from multiple load stations into the ductwork. This ensures high-performance, reliable, and clog-free conveying all while optimizing staff productivity.

3. Pneumatic Conveying: The bundles silently traverse the shaft and ductwork, propelled by a powerful pneumatic conveying system. This precision-engineered ductwork can span extensive distances, connecting to a compactor either on-site or located remotely. Additionally, the system’s technology allows for horizontal and vertical uplift conveyance, enabling waste to be efficiently transported from basements and other subterranean levels to its exact final destination.

4. Compaction and Ready for Pickup: A state-of-the-art slant screen separator extracts conveying air and momentum, guiding the bundles into a staging bin positioned above a highly efficient screw compactor. Computer-controlled doors facilitate the gentle release of bundles into the compactor, which subsequently seals shut. For added convenience, optional automated notifications can alert users when the system reaches full capacity.

ENVAC proudly offers the most advanced Automated Waste + Linen Removal System globally, combining cutting-edge technology and design to revolutionize waste management and linen handling practices.

Contact Envac North America directly to learn more about automated waste and soiled linen removal systems and how they can streamline the collection, transport and removal of waste and linen from your facility. Our systems remove infectious materials from corridors and elevators, decrease elevator requirements, reduce staff injuries, and increase profitability by reducing FTE’s, workers compensation claims and infection rates. You can reach us at get-facts@airconvey.com or 302-266-0555.