Increased productivity

Matrix, trim and waste removal

The PAC pneumatic trim and matrix waste removal solutions allow companies to produce more product in less time.

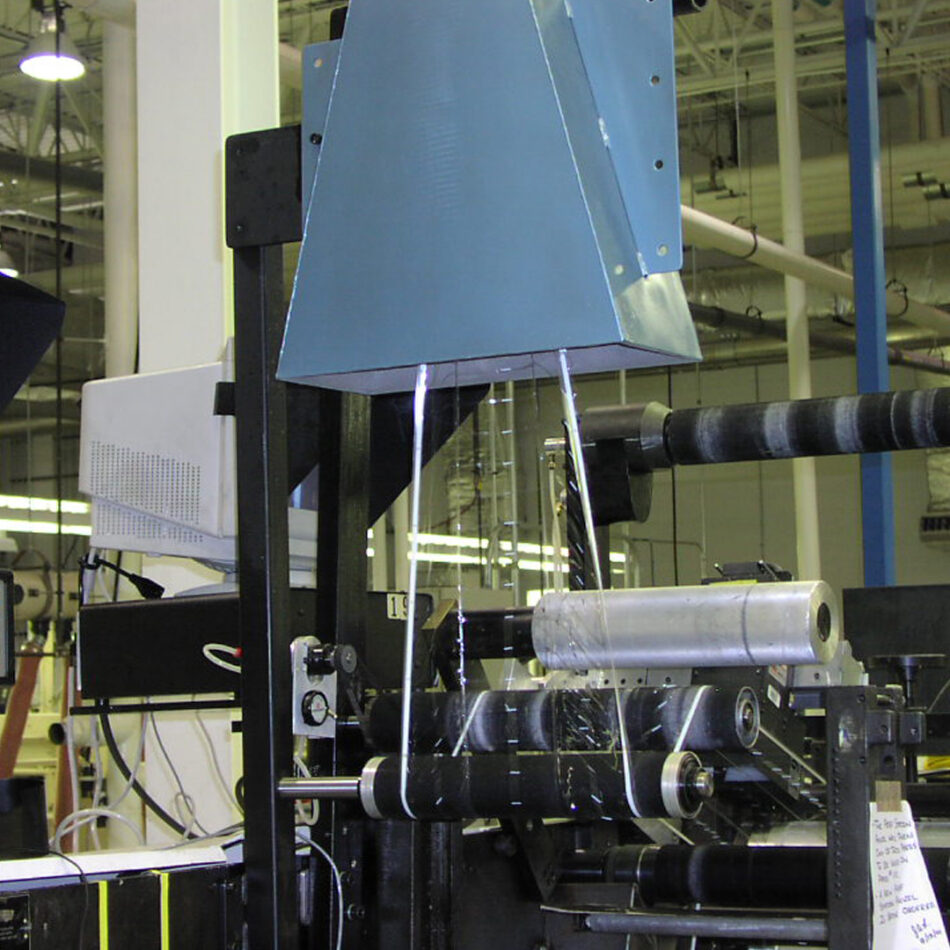

Our inline cutter/fan matrix waste removal systems capture matrix right at the press, whisking it away, chopping it up and depositing it in a waste bin or baler. This eliminates the inefficiencies associated with winding matrix, including wasting time to stop the press to remove the waste rolls of matrix. Because presses have fewer stops, registration is not lost, saving time and material. Material can be conveyed faster than it can be wound. Matrix winding keeps many companies from running their presses at higher speeds for fear of jams and tension breaks. PAC matrix removal systems keep up with your press when it is running at higher speeds, without windups or breakage.

Trim removal

PAC’s inline cutter/fan trim removal systems are fast, allowing you to run at faster speeds—producing more, faster.

In addition, the end product tends to be a better quality, because PAC’s systems eliminate tugging at the edges associated with other types of trim removal solutions.

Decreased downtime

PAC pneumatic trim and matrix waste removal systems decrease downtime by eliminating the common causes of clogs and jams, and by streamlining the waste removal process.

Avoid clogging

PAC systems chop trim and matrix waste into small pieces than can be sent through duct- work efficiently, swiftly and without buildups. The custom rotor design prevents jamming material wraps. PAC’s proprietary oil misters and duct coatings ensure that PSA materials do not adhere to themselves or system interiors.

Stop winding your matrix waste

The PAC’s matrix waste removal systems capture matrix waste right at the press. As a result, labelers, printers and converters who handle matrix and narrow web can eliminate the time-consuming process of winding matrix. Uptime is increased because:

- There is no need to stop presses to remove matrix waste rolls

- Web and tension breaks don’t stop the press

- Material can be conveyed faster than it can be wound

Less waste

The PAC trim and matrix waste removal systems allow companies to save on material costs in many ways:

Thinner edge trim

Our inline cutter/fan systems can capture edge trim and matrix waste as thin as 1/8 inch allowing productive use of more material.

Less press starting and stopping

The PAC matrix waste removal system eliminates the need for matrix winding eliminating the need to stop the press to remove matrix rolls. Removing matrix rolls wastes hundreds of feet of material each time.

Use less virgin material

Non-woven, and film and sheet companies can save on virgin material costs with a PAC Granulate Feed System (GFS). Our innovative two-hopper design allows for the highest scrap and trim to virgin resin ratio in extruder throughput, while maintaining a high level of quality of product.

Lower labor costs

PAC’s trim and label matrix removal systems help lower labor costs by automating several time-consuming processes and densifying waste so it can be handled more efficiently.

Automated trim and matrix waste handling

Labor costs associated with handling edge trim waste can amount to the equivalent of a full-time staff position. Our automatic trim removal systems run with almost no human interaction. With the help of a PAC Granulate Feed System, non-woven, and film and sheet companies can enjoy the labor-saving benefits of an automated closed loop reclaim and recycling system. Labelers, printers and narrow web companies also save dramatically with the elimination of the need to wind and manually remove rolls of matrix waste. Worker’s comp claims from heavy lifting will also decrease.

Densify waste and simplify handling

PAC’s in-line cutter/fan systems chop edge and matrix waste into small pieces, greatly decreasing waste volume and enhancing efficiency. Employees will no longer handle bulky waste rolls or numerous bins of loosely packed trim. Our Eco-PAC balers, and Waste densifiers further streamline the process by turning waste into easy-to-manage and simple-to-transport bales and bricks.

Other savings

Take fewer trips to the landfill

Uncut trim and rolls of waste matrix are bulky and unwieldy. PAC’s in-line cutter/fan systems densify waste by chopping it up into a confetti that can be packed into a much tighter space. As a result, waste containers fill up far more slowly with densified trim or matrix waste. Because more fits in a compactor, fewer trucks will head to the landfill offering savings on transport costs and landfill fees.

Energy efficient equipment

PAC’s engineering leads the industry in energy efficiency. Our equipment offers high speed/low horse-power which offers real savings in electrical costs and offers a greener footprint.